WES-TECH, INC.

In addition to the following information on American Manufacturing Drip Systems and Purestream ES BESST Systems, we also provide Purestream Extended Aeration plants, Purestream SBR's, and Purestream Microscreen Drum Filters.

American Manufacturing - Drip Dispersal Systems Why Drip Dispersal? Drip Dispersal is a land application system for dispersal of wastewater effluent in decentralized environments. Drip utilizes time dosed, low volume, equally distributed doses over an entire absorption area while at the same time providing final treatment and recycle back into the environment. Drip provides optimum conditions for groundwater recharge to the receiving environment. It is ideal for any size system: single family homes, schools, churches, state parks, communities, commercial sites, etc. Drip systems are aesthetically pleasing and are installed subsurface utilizing the “out-of-site, out-of-mind” theory. Drip fields lend themselves to passive recreation with year round natural irrigation. “Time dosed” systems provide for managing rest times between doses, peak flow notification, excess flow alarms and helps prevent soil saturation by maintaining an aerobic environment at the tubing interface. Drip is ideal for shallow installations, which maximizes the standoff to any site restrictions (i.e. rock, seasonal water table, etc.). Sloping sites and/or wooded sites are not a problem. Drip Dispersal is utilized in both warm and cold climates 365 days per year! Drip can reduce storage requirements and may offer a reduced area footprint compared to conventional systems. Drip is a reliable, proven and permanent option for your wastewater dispersal needs. Why “Perc-Rite®” Drip? The original drip technology! The world-renowned “Perc-Rite®” technology was the first drip dispersal system developed for use in wastewater applications. The “Perc-Rite®” Drip System is a complete wastewater dispersal system utilizing pressure compensating drip tubing, automatic disc filtration, automatic periodic forward field flushing and efficient effluent pumps with totalizing flow meter and state-of-the-art controls plus design standards for long term sustainable onsite wastewater installations. The pressure compensating drip tubing allows for complete equal distribution of the effluent. Disc filtration provides the necessary protection for the drip emitters prior to the drip field. The disc filters automatically backwash at preset intervals. The “Perc-Rite®” Drip System also automatically forward flushes the drip tubing on a periodic basis at the generally accepted engineering standard for minimum scouring velocity of 2.0 ft/sec. The “Perc-Rite®” System sets the standard for excellence in drip technology!

Drip Systems Installation List | |||

|

|

|

|

Year |

Job Name |

Location |

GPD |

1999 |

Bridlewood at Thornbury |

Chester Co., PA |

100,000 |

2000 |

Misty Meadows Community |

Morgantown, PA |

3,750 |

2000 |

Hawk Mountain Boy Scout Camp |

Schuylkill Co., PA |

36,000 |

2001 |

Pocopson Elementary School |

Pocopson, PA |

8,220 |

2001 |

Hawk Mountain Bird Sanctuary |

Berks Co., PA |

3,800 |

2002 |

French Creek Elementary School |

Pottstown, PA |

5,400 |

2002 |

Del Val College |

Doylestown, PA |

3,600 |

2003 |

Lancaster Bible Church |

Lancaster Co., PA |

4,500 |

2003 |

Wharton Elementary School |

Fayette Co., PA |

5,300 |

2003 |

Falling Waters House |

Fayette Co., PA |

4,300 |

2003 |

Bonnie Brook Nursing Home |

Butler Co., PA |

2,300 |

2003 |

Little Pine State Park |

Lycoming Co., PA |

7,125 |

2003 |

R.B. Winter State Park |

Union Co., PA |

3,900 |

2004 |

Eagelview II |

Delaware Co., PA |

7,500 |

2005 |

Woodbine Airport |

Cape May Co., NJ |

100,000 |

2006 |

Washington Twp. Elementary School |

Northampton Co., PA |

6,600 |

2007 |

Coatesville Catholic |

Chester Co., PA |

10,580 |

2007 |

Hundredfold Farm |

Adams Co., PA |

4,500 |

2007 |

Wrigley/New Daleville |

Chester Co., PA |

34,000 |

_____________________________

Purestream ES - BESST System

The BESST Process Purestream BESST System Local Installations Job Name Location Tanks GPD Timberly Farms Plumstead Twp., PA Steel 17,000 Eagleview Development Newtown Square, PA Steel 7,500 Great Wolf Scot Run, PA Steel 90,000 Woodbine Woodbine, NJ Steel 100,000 Belvidere Belvidere, NJ Concrete 500,000 Windsor Delaware County, PA Steel 5,400 Sunnyside Hopewell Twp., PA Steel 21,000 Dublin Twp. Dublin Twp., PA Steel 45,000 Big Run Municipal Authority Jefferson County, PA Steel 110,000 Rorke Development Chester County, PA Steel 20,000 Shelly Square Harleysville, PA Steel 15,000 Coatesville Catholic Chester County, PA Steel 12,000 Wrigley/New Daleville Chester County, PA Steel 34,000 Perkiomen Montgomery County, PA Concrete 120,000 Arrowhead Lake Pocono Lake, PA Steel 400,000 Mobile Gardens Seaford, DE Steel 60,000 Upper Bern/Shartlesville Shartlesville, PA Concrete 100,000 Keats Glen/DCCC Chester County, PA Steel 25,000 Penn Twp. Jennersville, PA Concrete 350,000 Cedar Square Seaville, NJ Steel 33,000

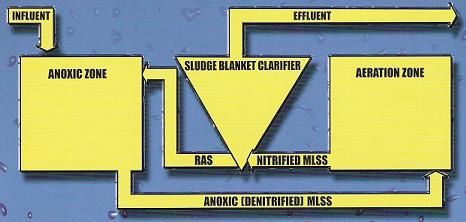

The raw wastewater enters the anoxic zone first where it is mixed with nitrified Return Activated Sludge from the sludge blanket clarifier. Submersible mechanical mixers are installed in the anoxic compartment to facilitate homogeneous mixing, and increase the denitrification efficiency. From here, the mixed liquor flows in a plug flow manner to the aeration zone where fine bubble diffusers provide the oxygen required for nitrification and BOD5 reduction.

After aeration, the mixed liquor enters the bottom of the separation compartment where solids and treated effluent are separated by a patented velocity gradient sludge blanket clarifier. The operation of the clarifier is self-regulating. As the flow enters the bottom of the clarifier, a velocity gradient is created in such a way that the bottom 2 to 3 feet of solids are kept in a completely mixed state which eliminates the need for the operator to scrape the clarifier (solids will not bulk). While the solids rise, their velocity decreases creating a sludge based, fluidized bed filter, which removes fine and colloid particles from the treated effluent. Trapping these particles increases the weight of the solids, causing them to drop to the bottom of the clarifier, where they are returned to the anoxic zone by an airlift or mechanical pump. The internal circulation loop created by this plug flow is typically set at a minimum of four (4) times the average daily flow, increasing nitrification and denitrification dramatically.

The effluent weir is equipped with a scum baffle and scum skimmer which aids in the reduction of TSS in the effluent. The efficiency of the process, and velocity gradient sludge blanket clarifier, produces effluent quality well below 10 mg/l BOD5, < 10 mg/l TSS, less than 1 mg/l ammonia, less than 10 mg/l total nitrogen (<5 mg/l TKN) and effluent phosphorous levels between 2 and 3 mg/l by "Luxury Uptake" and less than 0.5 mg/l with the use of metal salts.